While expanded metal and perforated metal may look and sound similar, there are several important differences between them. These two products can be used for many of the same industrial applications, but each provides specific benefits that make them ideally suited for particular uses.

Perforated metals are often used for architectural applications such as building facades, fences and partitions. Because perforated metals are punched and cut, dies can be designed to cut patterned shapes into sheet metal for a variety of purposes, both decorative and functional. The shape of metal perforations can determine a material’s usefulness for blocking microwaves, sound waves or light; perforated metals are used in all these industries.

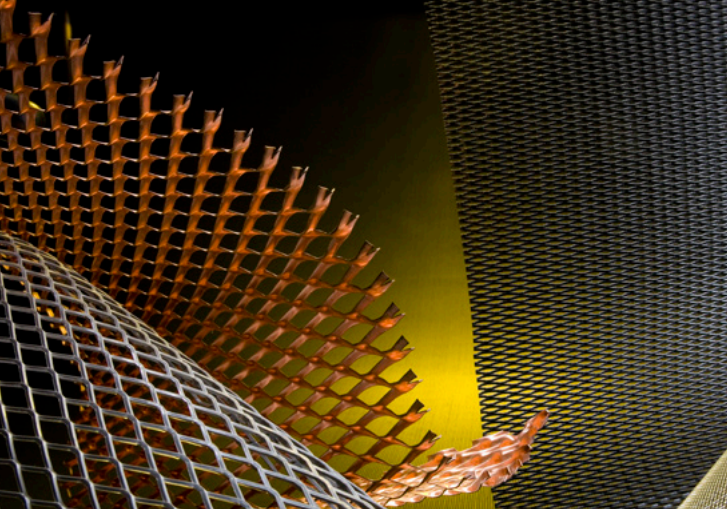

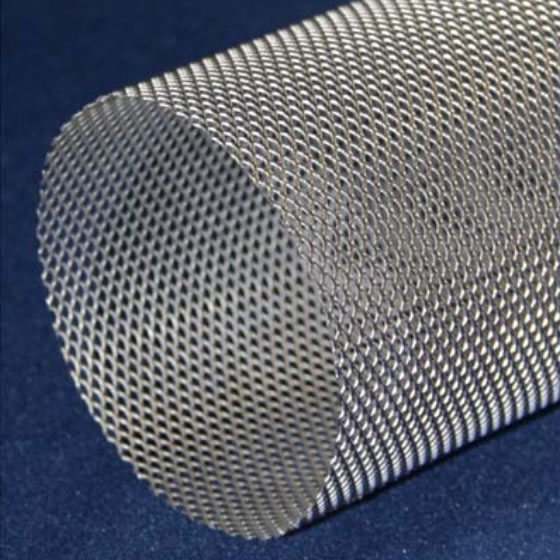

Expanded metal sheets, while capable of many of these applications, excel in a different area entirely. The stair treads, walkways, catways and floor gratings found so commonly in industrial facilities, construction sites and even many commercial buildings are made from industrial expanded metal. Unlike perforated metals, expanded metals are slit and stretched, creating a pattern of three dimensional structures and giving the metal more strength. This slitting and stretching process sets expanded metals apart from perforated metals in cost and fabrication time. Because expanded metals are slit and stretched, there is virtually no waste material, significantly lowering fabrication costs. It’s also a fairly quick process, making custom expanded metal stair tread orders fast and cost-effective.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services