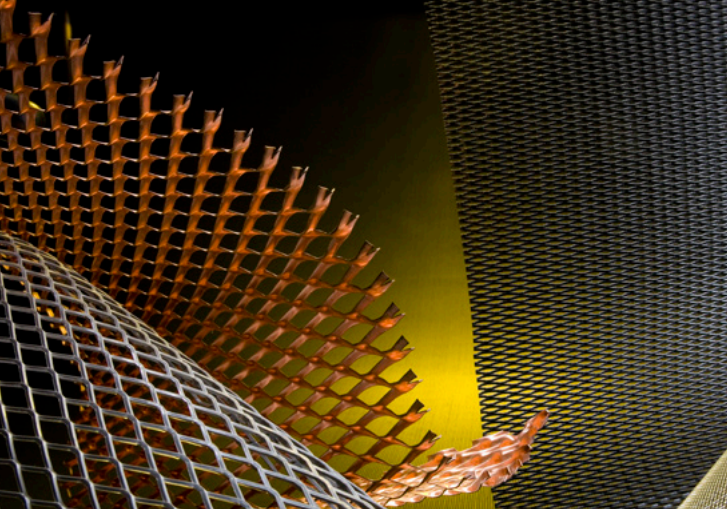

Expanded steel is a unique material widely utilized in various industries. It derives its name from the manufacturing process that involves stretching a sheet of steel, creating a pattern of interconnected diamond-shaped openings. This structural design grants expanded steel its distinctive characteristics and makes it suitable for numerous applications. Read More…

At Zauderer Associates, Inc., we specialize in providing high-quality expanded metals tailored to meet diverse industrial needs. Our extensive range of expanded metal products offers versatile solutions known for their strength, durability, and reliability. Leveraging advanced manufacturing techniques, we supply precision-engineered materials ideal for applications such as filtration, security...

Our expanded metal is ideal for a wide range of applications and our teams will work with you every step of the way to guarantee your satisfaction. Our goal is to exceed your expectations and we take pride in providing our customers with outstanding services.

At Expanded Solutions L.L.C., we take pride in producing high-quality expanded metals that serve as durable, versatile solutions for a wide range of applications. We engineer our products to meet demanding performance requirements in industries such as construction, filtration, security, and manufacturing. By expanding metal sheets through precision cutting and stretching processes, we create...

More Expanded Steel Manufacturers

Production of Expanded Steel

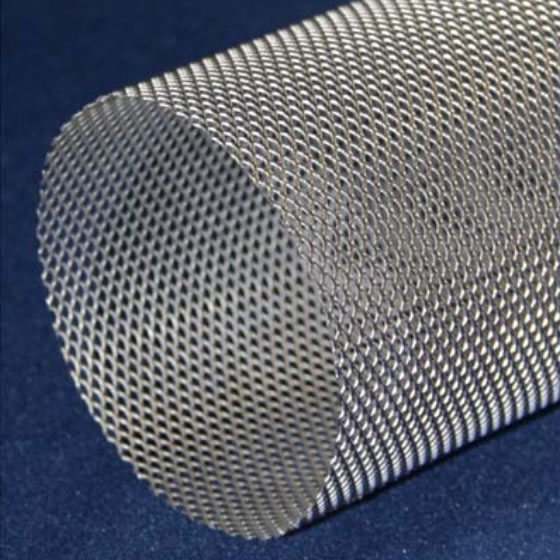

Compared to regular steel, the production of expanded steel involves an additional step. The manufacturing process begins with a sheet steel, which is then sheared and stretched using specialized machinery. This stretching creates a pattern of uniform diamond-shaped openings, resulting in a mesh-like structure. The metal sheet expands without losing its structural integrity, leading to a robust and versatile material that serves diverse purposes.

Processes Used to Create Expanded Steel

Expanded steel can be created through various processes, resulting in different structural configurations. The expanded metal mesh process for creating expanded steel involves stretching a metal sheet to form a pattern of interconnected diamond-shaped openings, providing strength and versatility. Flattened expanded steel, meanwhile, is produced by passing the expanded metal through heavy rollers, resulting in a flattened surface with improved aesthetics and reduced sharp edges. Another process used to create an additional variation of expanded steel is known as raised expanded steel. The process of raised expanded steel involves deliberately raising the diamond-shaped openings of the expanded metal mesh to create a three-dimensional pattern with enhanced structural integrity and depth. Each of these processes offer expanded steel with unique characteristics, catering to a wide range of applications.

Types of Steel Used for Expanded Steel

Expanded steel encompasses a variety of steels, each offering specific properties for diverse applications. Carbon steel, composed primarily of iron and carbon, is widely used in expanded steel due to its strength and durability. It finds utility in applications such as platforms, fencing, and reinforcement. Stainless steel, an alloy of iron, chromium, and other elements, meanwhile, is chosen for its corrosion resistance and aesthetic appeal. Expanded stainless steel is utilized in architectural elements, interior design, and food processing equipment. Galvanized steel, coated with a layer of zinc, on the other hand, offers enhanced corrosion resistance and is commonly employed in outdoor applications. Furthermore, high-strength low-alloy (HSLA) steel, with its excellent strength-to-weight ratio, serves structural components in construction and heavy machinery. Additionally, tool steel, known for its hardness and wear resistance, finds application in specialized industrial tools and dies. Likewise, alloy steel, formulated with specific alloying elements, provides a combination of strength, toughness, and resistance to wear or corrosion. Finally, expanded steel made from alloy steel caters to industries such as aerospace, automotive, and oil and gas.

Considerations Regarding Expanded Steel

While expanded steel offers numerous benefits, it is essential to acknowledge some considerations. One aspect to consider is the potential for sharp edges in the expanded metal, which can pose safety concerns during handling or installation. Additionally, expanded steel may entail considerations for certain applications requiring fine filtration or load-bearing capacities which could be beyond its capabilities.

Manufacturers’ Efforts to Address These Considerations

Manufacturers of expanded steel have taken proactive measures to address these considerations. To mitigate safety concerns, they offer options with rounded or flattened edges, reducing the risk of injury. Furthermore, advancements in manufacturing techniques enable the production of specialized expanded steel with enhanced load-bearing capabilities, ensuring it meets the requirements of demanding applications.

Benefits of Expanded Steel

Expanded steel offers a range of advantages. Its inherent strength and durability make it suitable for demanding environments and high-traffic areas. The versatility of expanded steel also allows for customization in terms of mesh size, thickness, and material, catering to specific project needs. The unique mesh pattern, meanwhile, provides excellent ventilation, light transmission, and drainage properties. Additionally, expanded steel exhibits enhanced aesthetic appeal, allowing for creative design possibilities, while remaining cost-effective compared to alternative materials.

Applications of Expanded Steel

Expanded steel finds diverse applications across numerous industries. In the aerospace sector, for instance, it is utilized in the manufacturing of components such as aircraft grilles, ventilation systems, and engine baffles due to its lightweight nature and structural strength. The automotive industry also employs expanded steel in radiator grilles, exhaust system baffles, and structural components, benefiting from its durability and ability to withstand harsh environments. In the oil and gas industry, meanwhile, expanded steel is used in filtration systems, walkways, and platforms due to its corrosion resistance and high load-bearing capacity. Additionally, fencing applications benefit from expanded steel's ability to provide sturdy and secure enclosures, whether for residential, commercial, or industrial purposes. Likewise, in the field of architecture, expanded steel is used for facades, partitions, and decorative elements, allowing for unique design possibilities while ensuring structural integrity. Interior design applications, meanwhile, encompass wall panels, ceiling tiles, and room dividers, where expanded steel adds a modern and industrial aesthetic. Furthermore, the food processing industry relies on expanded steel for equipment such as conveyor belts, sieves, and screens, benefiting from its hygiene, easy cleaning, and corrosion resistance. In outdoor applications, expanded steel serves as walkways, catwalks, and grating for its robustness, drainage properties, and non-slip surfaces. Construction projects also utilize expanded steel in stair treads, safety barriers, and reinforcing materials due to its strength and structural stability and heavy machinery manufacturers employ expanded steel for machine guarding, enclosures, and filtration systems, taking advantage of its durability and versatility. Finally, expanded steel is used in the production of industrial tools and dies, where its hardness, wear resistance, and dimensional stability are crucial.

Choosing the Right Expanded Steel Supplier

To ensure you have the most productive outcome when purchasing expanded steel from an expanded steel supplier, it is important to compare several companies using our directory of expanded steel suppliers. Each expanded steel supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each expanded steel business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple expanded steel companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services