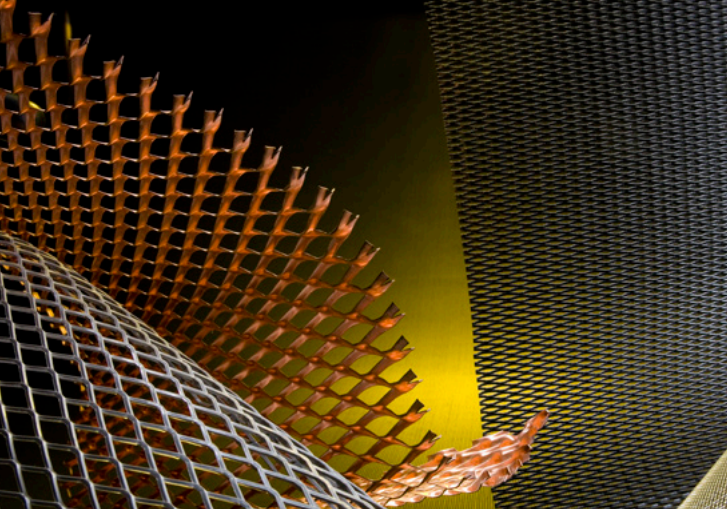

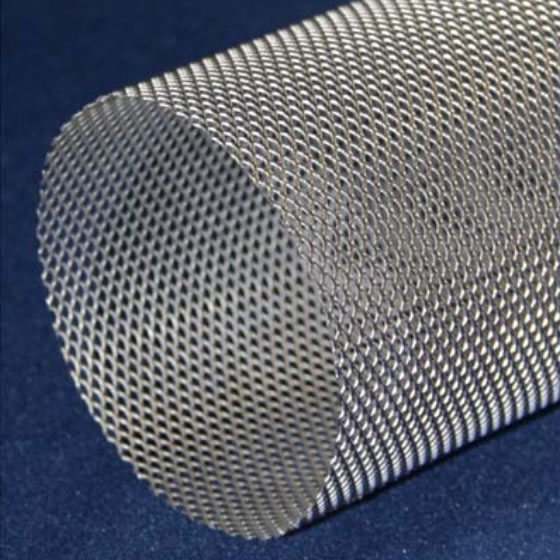

Expanded copper is a plate or sheet of copper that has been sliced and stretched into a mesh pattern. The mesh pattern can be straight with all the rows and columns aligned or staggered (which offers the largest open area). Various mesh patterns are available depending on the intended use of the expanded copper since the proportion of open surface affects how much space is available for the flow of air, water, and light. Although many designs can be made, the copper is typically stretched with spaces that are shaped like diamonds. Read More…

At Zauderer Associates, Inc., we specialize in providing high-quality expanded metals tailored to meet diverse industrial needs. Our extensive range of expanded metal products offers versatile solutions known for their strength, durability, and reliability. Leveraging advanced manufacturing techniques, we supply precision-engineered materials ideal for applications such as filtration, security...

Our expanded metal is ideal for a wide range of applications and our teams will work with you every step of the way to guarantee your satisfaction. Our goal is to exceed your expectations and we take pride in providing our customers with outstanding services.

At Expanded Solutions L.L.C., we take pride in producing high-quality expanded metals that serve as durable, versatile solutions for a wide range of applications. We engineer our products to meet demanding performance requirements in industries such as construction, filtration, security, and manufacturing. By expanding metal sheets through precision cutting and stretching processes, we create...

More Copper Expanded Metal Manufacturers

Expanded Copper: Properties, Manufacturing, Applications, and Buying Guide

Copper is renowned for its malleability, ductility, and exceptional electrical conductivity, making it a preferred material across various industries. Its adaptability allows copper to be easily molded and treated both before and after the metal expansion process, setting it apart from other metals. While metals such as stainless steel, hot-rolled steel, cold-rolled steel, and aluminum can also undergo expansion, expanded copper is often chosen for applications requiring superior corrosion resistance. This is particularly important in environments exposed to moisture, chemicals, or outdoor conditions, where protection against rust and oxidation is paramount.

What is Expanded Copper?

Expanded copper refers to a type of copper mesh or lattice formed by simultaneously slitting and stretching a copper sheet, transforming it into a pattern of interconnected strands and openings. This process results in a single-piece, open mesh structure that offers strength, rigidity, and excellent airflow. Expanded copper mesh is used in a wide range of commercial, industrial, and architectural applications, thanks to its unique combination of mechanical properties and visual appeal.

Expanded Copper Manufacturing Process

Although technology has advanced, the first step of the modern copper expansion process still closely resembles its historical origins. The process starts with rolling and shaping the raw copper mineral into flat plates or expanded metal sheets. Today’s computerized manufacturing technology offers significant improvements in speed, accuracy, and pattern consistency, ensuring high-quality results for every batch of expanded copper mesh.

The manufacturing workflow includes the following stages:

- Preparation: Raw copper is rolled and flattened into sheets of the desired thickness and width.

- Feeding: The prepared copper sheets are fed into an automated or semi-automated expansion machine.

- Slitting and Stretching: Knife-like dies cut the metal in an alternating offset pattern, while the sheet is simultaneously heated and pulled through rollers. This action stretches the pre-cut holes, expanding the sheet and forming the open mesh structure.

- Finishing: The expanded copper is either wound into coils for further processing or sliced into sheets of specific dimensions based on customer requirements.

- Quality Control: The finished expanded copper mesh undergoes inspection to verify uniform patterning, consistent thickness, and mechanical properties such as tensile strength and flexibility.

During the expansion process, the thickness of the copper sheet decreases while its overall length can increase up to tenfold. The resulting product is a robust, single-piece open latticework, which is ideal for applications where strength-to-weight ratio, durability, and enhanced circulation are crucial. When selecting a copper sheet for expansion, it is vital to consider the desired mesh shape, open area proportion, and final sheet dimensions to ensure optimal performance in the intended application.

Types of Expanded Copper

Expanded copper mesh is available in several distinct varieties, each tailored to specific functional and aesthetic requirements. The most common types of expanded copper include:

Standard Expanded Copper

Standard expanded copper features uniform angled strands and bonds. This design increases structural strength and rigidity while allowing maximum airflow and light transmission. Standard expanded mesh is available in various gauges and opening sizes, making it a cost-effective solution for a broad range of applications. Its hard, raised, non-slip surface is particularly useful in flooring, walkways, and protective screening.

Flattened Expanded Copper

Flattened expanded copper is produced by cold rolling standard expanded mesh, compressing the mesh to create a smooth, flat surface. The flattening process increases the sheet’s length by approximately 5%, while reducing its thickness. Flattened expanded copper is preferred in applications where a sleek, low-profile finish is desired. It is widely used in architectural cladding, interior design, and electronics shielding due to its improved aesthetics and reduced snagging risk.

Hexagonal Expanded Copper

Hexagonal expanded copper is characterized by its unique hexagon-shaped openings, as opposed to the conventional diamond pattern. The hexagonal configuration enhances the mesh’s strength and stability, while offering improved passage for liquids, gases, light, heat, and sound. This makes hexagonal expanded copper ideal for applications such as filtration, acoustic panels, and decorative screens where high permeability and structural reinforcement are required.

Architectural Expanded Copper

Architectural expanded copper meshes feature intricate diamond or custom patterns, optimized for both function and design. These meshes provide enhanced privacy, security, and ventilation, while serving as attractive elements in building façades, sunshades, partitions, and balustrades. The natural patina of copper adds to the aesthetic value, making architectural expanded copper a popular choice for interior and exterior design projects seeking a blend of beauty and utility.

Micro Expanded Copper

Micro expanded copper is fabricated from light-gauge copper sheets with extremely small apertures. Available in standard, flattened, hexagonal, and square patterns, micro expanded copper is commonly used in fine filtration, EMI/RFI shielding, and precision electronic components. Its fine mesh structure enables it to trap small particles, block electromagnetic interference, and offer protection in sensitive applications.

Key Benefits of Expanded Copper

Expanded copper offers a host of advantages that make it an optimal choice for demanding industrial, commercial, and architectural projects. Noteworthy benefits include:

- Cost-effectiveness: The expansion process allows a small amount of copper to cover a larger area, maximizing material utilization and reducing overall project costs.

- Minimal Waste: Production and processing of expanded copper mesh generate minimal scrap compared to other manufacturing methods.

- Excellent Conductivity: Copper’s inherent electrical, magnetic, and thermal conductivity make expanded copper ideal for electromagnetic shielding, electrical enclosures, and heat dissipation applications.

- Corrosion Resistance: Copper’s natural ability to resist rust and corrosion makes it suitable for outdoor, marine, and chemically aggressive environments.

- High Strength-to-Weight Ratio: Expanded copper meshes are stronger and lighter than welded or woven alternatives, enabling them to support significant loads without excessive weight.

- Enhanced Circulation: The open mesh structure permits optimal flow of air, light, sound, heat, and fluids, making expanded copper suitable for ventilation, filtration, and acoustic paneling.

- Design Flexibility: Copper’s malleability enables the creation of complex mesh patterns and shapes, tailored to unique architectural or industrial specifications.

- Improved Appearance: The distinctive mesh pattern and natural copper luster enhance the visual appeal of building façades, interior partitions, and decorative features.

- Ease of Fabrication: Expanded copper is easier to cut, shape, and install compared to other metals, reducing labor costs and simplifying onsite modifications.

- Compatibility: Expanded copper meshes can be combined with other materials, such as glass, concrete, or composites, to reinforce structures and improve mechanical properties.

- Acoustic Properties: Specially designed copper meshes can be used for soundproofing, noise reduction, and improving room acoustics in commercial and industrial settings.

Top Applications and Use Cases for Expanded Copper

Are you exploring how expanded copper mesh can enhance your next project? Expanded copper’s versatility makes it invaluable in a variety of industries and applications. Common uses include:

- Architecture and Design: Building cladding, sunscreens, decorative panels, room dividers, stair railings, and feature walls that require both structural support and visual impact.

- Electrical and Electronics: EMI/RFI shielding, grounding, circuit board protection, and enclosures requiring superior conductivity and static dissipation.

- Filtration Systems: Air, fluid, and gas filters for HVAC systems, industrial filtration, and water treatment, utilizing micro expanded copper mesh for fine particle capture.

- Acoustics and Sound Control: Acoustic panels, soundproofing barriers, and speaker grilles where controlled airflow and sound attenuation are needed.

- Industrial Equipment: Machine guards, safety screens, flooring, walkways, and cable trays where lightweight strength and corrosion resistance are critical.

- Energy Sector: Battery components, fuel cell electrodes, and heat exchangers leveraging copper’s high electrical and thermal conductivity.

- Automotive and Aerospace: Radiator grilles, heat shields, and protective screens requiring lightweight, durable, and conductive materials.

- Security and Safety: Protective mesh for windows, doors, fencing, and enclosures in high-security or hazardous environments.

- Art and Sculpture: Creative installations and sculptures where the unique texture and patina of copper mesh contribute to artistic expression.

Buyer’s Guide: How to Choose the Right Expanded Copper Mesh

With a range of expanded copper mesh types and specifications available, selecting the right product for your application can be a complex decision. Consider the following factors to ensure you choose the best expanded copper mesh or sheet for your needs:

- Mesh Pattern and Opening Size: Evaluate the required level of airflow, light transmission, or filtration versus the need for strength and rigidity. Choose between standard, flattened, hexagonal, or micro mesh patterns based on application requirements.

- Sheet Thickness (Gauge): Thicker meshes provide greater load-bearing capability and durability, while thinner meshes are lighter and more flexible. Match the gauge to your structural demands and installation environment.

- Material Grade: Select the appropriate copper alloy (such as C110, C122, or custom alloys) to balance conductivity, corrosion resistance, and mechanical properties.

- Finish and Surface Treatment: Consider surface finishes such as polished, brushed, or patinated copper for aesthetic projects, or coatings for enhanced corrosion resistance in harsh environments.

- Form Factor: Decide if you require sheets, rolls, or custom shapes, and verify the mesh’s compatibility with your installation or fabrication processes.

- Compliance and Standards: Ensure the expanded copper mesh meets relevant industry standards for electrical, safety, or architectural applications.

- Customization: Many suppliers offer custom expansion patterns, sheet sizes, and finishing options. Discuss your project specifications with potential manufacturers to achieve the ideal solution.

Frequently Asked Questions About Expanded Copper

- What is the lifespan of expanded copper in outdoor applications?

Due to copper’s natural resistance to corrosion and weathering, expanded copper mesh can last decades in exterior environments, developing a desirable patina over time which enhances both its durability and appearance. - Can expanded copper be recycled?

Yes, copper is 100% recyclable without loss of quality. Scrap expanded copper mesh can be reclaimed and reused, supporting sustainable manufacturing practices. - How does expanded copper compare to expanded aluminum or steel?

While all expanded metals share similar structural properties, copper stands out for its superior electrical and thermal conductivity, corrosion resistance, and aesthetic value. However, it is generally more expensive than aluminum or steel. - What are typical lead times for custom expanded copper orders?

Lead times vary based on order complexity, volume, and supplier capacity. Standard sizes may ship quickly, while custom patterns or finishes require additional processing time. Check with suppliers for accurate delivery estimates. - How do I clean and maintain expanded copper mesh?

Routine cleaning with mild soap and water is sufficient. For architectural applications, a protective coating may be applied to preserve the finish and slow patina development. Avoid abrasive cleaners that could damage the surface.

Comparing Expanded Copper Suppliers: Key Decision Factors

When sourcing expanded copper mesh, choosing the right supplier ensures consistent product quality, reliable delivery, and responsive customer support. Here are important questions and prompts to guide your supplier evaluation:

- Does the supplier offer a variety of expanded copper types and customization?

Look for suppliers with a broad product range, including standard, flattened, hexagonal, and micro mesh, as well as the ability to create custom patterns or sizes. - What certifications or quality standards does the company uphold?

Certifications such as ISO 9001 or industry-specific standards demonstrate a commitment to quality assurance and process control. - Can the supplier provide samples or technical data sheets?

Requesting samples or detailed specifications can help verify product suitability before placing a bulk order. - What are the supplier’s minimum order quantities and lead times?

Confirm whether the supplier can accommodate your project’s scale and timeline. - Does the supplier offer additional services such as cutting, fabrication, or finishing?

Value-added services can streamline your manufacturing process and reduce costs. - How does pricing compare across different suppliers?

Obtain multiple quotes to ensure competitive pricing without sacrificing quality or service.

How to Request a Quote or Find an Expanded Copper Manufacturer

For the most constructive outcome when selecting an expanded copper supplier, it is important to compare several businesses using our comprehensive directory of expanded copper suppliers. Each supplier is profiled with detailed information about their manufacturing capabilities, industry experience, and product offerings.

To streamline your sourcing process:

- Review supplier business profiles to assess experience, capabilities, and product quality.

- Use our patented website previewer to quickly explore each supplier’s website and specialization.

- Request samples or technical information to verify mesh specifications and performance.

- Leverage our simple RFQ (Request For Quote) form to contact multiple expanded copper companies simultaneously, saving you time and ensuring a competitive selection process.

- Communicate directly with suppliers to discuss project requirements, customization options, and delivery timelines.

Ready to get started? Request a quote from leading expanded copper mesh manufacturers today to discover solutions that meet your technical, budgetary, and aesthetic needs.

Conclusion: Why Choose Expanded Copper Mesh?

Expanded copper mesh is an innovative, high-performance material offering unmatched value across a spectrum of industries. Its unique blend of strength, conductivity, corrosion resistance, and aesthetic appeal makes it the material of choice for applications ranging from architectural design to industrial equipment and electronics. By understanding the manufacturing process, types, benefits, and selection criteria, you can confidently specify the right expanded copper product for your next project.

Still have questions about expanded copper mesh, copper sheet expansion, or custom mesh solutions? Contact a trusted expanded copper supplier or browse our directory to find the perfect partner for your project.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services