More Expanded Metal Manufacturers

Manufacturers often create expanded metal products for both decorative and functional purposes. These versatile industrial materials offer a robust yet lightweight solution, enhancing the strength and durability of any product made partially or entirely from them. Expanded metals provide protection while still allowing air, light, and fluids to flow through, making them an ideal choice for a wide range of commercial, architectural, and industrial applications. Whether you are seeking expanded metal sheets for construction, expanded metal mesh for fencing, or specialty expanded metal panels for architectural design, understanding the benefits and applications of this material can help you make an informed purchasing decision.

Products Produced

Expanded metal is a versatile material utilized in a myriad of applications, making its way into numerous products thanks to its unique characteristics and superior performance. One of the most prevalent products crafted from expanded metal is expanded metal grating. This type of grating is extensively employed in industrial settings, walkways, catwalks, safety platforms, mezzanines, and manufacturing plants. Its open design facilitates efficient drainage and natural ventilation while offering robust support for heavy loads and foot traffic. Heavy-duty expanded metal grating is often chosen for areas that require both strength and slip resistance, such as loading docks, stair treads, and maintenance platforms.

Another significant use of expanded metal is in fencing and security products. The interlocking pattern of expanded metal is ideal for fencing, providing both visibility and security in various environments, such as airports, prisons, correctional facilities, sports arenas, and commercial properties. Expanded metal fencing creates strong barriers that are difficult to penetrate or vandalize, making them a preferred option for perimeter security and property protection.

Expanded metal is widely utilized in architectural and decorative applications, offering both functionality and visual appeal. Architectural meshes crafted from expanded metal enhance the aesthetic of buildings and facades, delivering a distinctive and contemporary look. These meshes serve as sunscreens, privacy screens, and artistic installations, allowing designers to creatively manipulate light and shadow. In modern architecture, expanded metal facades are used to create innovative building exteriors, sunshades, and cladding systems that combine beauty with energy efficiency.

Furthermore, expanded metal is used in automotive products like radiator grilles, battery covers, heat shields, and protective covers, valued for its lightweight and durable properties. In the transportation industry, expanded metal parts are preferred for their ability to withstand impact while minimizing weight, contributing to fuel efficiency and vehicle safety.

In the realm of filtration and screening, expanded metal plays a vital role. It’s used to create air filters, oil filters, and screens for a variety of industrial processes. The precise openings in the expanded metal facilitate efficient filtration, making it the ideal choice for separating particles in liquids and gases. Expanded metal screens are commonly found in HVAC systems, water treatment facilities, and food processing plants.

Furthermore, expanded metal plays a crucial role in the construction industry as reinforcement for concrete and masonry. When used as concrete reinforcing mesh, expanded metal significantly enhances the structural integrity and load-bearing capacity of concrete structures, thereby improving their durability and safety. Expanded metal lath is commonly used as a plaster base in stucco and masonry work, providing better adhesion and crack resistance.

Other notable applications include machine guards, shelving, partitions, cable trays, speaker grilles, and lighting fixtures. The adaptability of expanded metal makes it a prized material across numerous industries, resulting in the creation of an array of diverse products. Whether used in grating, fencing, architectural meshes, automotive components, or filtration systems, expanded metal is crucial in fulfilling structural, functional, and aesthetic needs in a variety of applications.

History

In 1884, John French Golding revolutionized the mining industry in the United Kingdom with his invention of the expanded metal process. His aim was to create a durable tray or metal screen that miners could use to sort coal more efficiently. Prior to Golding’s innovation, miners relied on sorting tools crafted from metal strips or woven wire, which were both inefficient and lacked standardization, as well as strength. Golding’s breakthrough involved using a single metal sheet, resulting in screens far more durable than their predecessors. Moreover, the expanded metal process produced screens with consistent and uniform open areas, greatly enhancing their effectiveness for sorting and filtration.

Five years after pioneering metal expansion, Golding and a group of industry experts combined their knowledge and research to establish a new company. Initially named the British Metal Expansion Company, it was later rebranded as the Expanded Metal Company Limited, based in London. For several years, the Expanded Metal Company held a monopoly on metal expansion in Europe, possessing exclusive rights to the process. This early dominance helped establish expanded metal as a standard industrial material throughout Europe and beyond.

In the 1890s, Eli Hendrick, an American innovator, invented the punching machine, which served as the precursor to modern perforating punches. These perforating punches enable the creation of perforated metals, closely related to expanded metals, and opened new possibilities for industrial filtration, screening, and ventilation products.

Charles H. Schrammel was the first person in the United States to receive a patent for expanding metal. Awarded in 1910, his innovative work significantly improved the metal expansion process. Schrammel introduced sheet metal rolling to the process and altered the angle of metal mesh dividers, resulting in better textures for gripping and enhanced performance in safety applications.

Over the past century, the metal expansion process has largely remained consistent, with notable advancements driven by technological progress. Innovations such as automation, digital perforation, the establishment of standards organizations, and the advent of CNC machining have revolutionized the field. While the rise of plastics has slightly reduced the market share for expanded metals, the industry continues to flourish. Recently, a revived interest in classic architectural styles has spurred renewed demand for architectural perforated and expanded metals, leading to a significant increase in business for the expanded metal products industry. Modern manufacturers now offer a wide range of custom expanded metal solutions to meet the evolving needs of the construction, automotive, and design sectors.

Materials

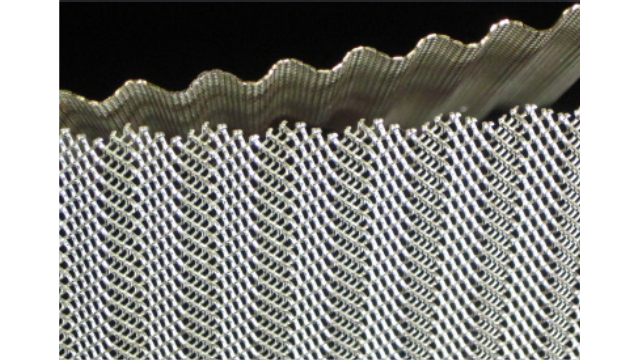

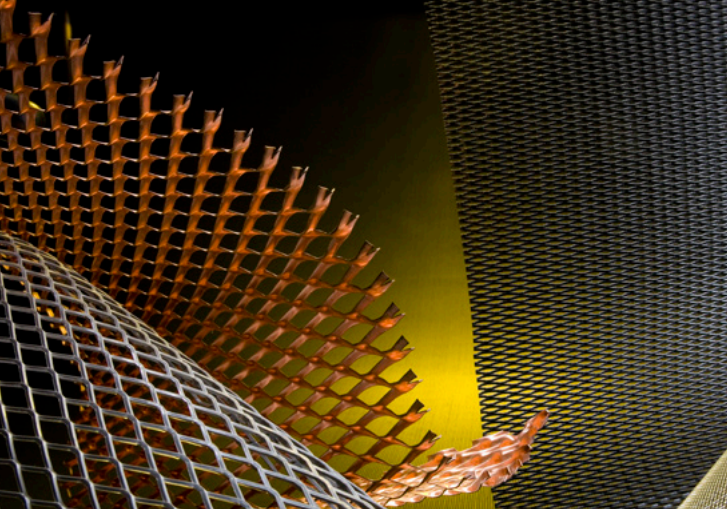

Manufacturers craft expanded metal products from a variety of metals, with copper, aluminum, stainless steel, and titanium being the most frequently chosen. These metals are known for their exceptional strength and corrosion resistance, while still maintaining a relatively lightweight profile. After expansion, they can all be cold rolled to reduce their thickness, ensuring a more uniform and smooth surface. Selecting the right material is key to achieving desired properties such as durability, conductivity, corrosion resistance, and weight savings.

Copper, a naturally occurring non-ferrous transition metal, is renowned for its exceptional electrical and thermal conductivity, antimicrobial properties, corrosion resistance, strength, and distinctive color. Manufacturers harness the versatility of copper expanded metal to create a diverse array of products, including metal grating, enclosures, filters, radiators, walkways, heat sinks, decorative ornaments, and intricate decorative metal mesh. Copper expanded metal mesh is also used in EMI/RFI shielding, electrical enclosures, and architectural accents where both performance and appearance matter.

Aluminum, a naturally occurring element, is rarely used in its pure form but stands out for its lightweight, durability, and superior corrosion resistance compared to carbon steel. Notably, aluminum strengthens in cold temperatures instead of becoming brittle. Expanded aluminum is versatile, finding applications in refrigerator and freezer enclosures, guards, flooring, walkways, grilles, electronic and automotive components, marine and aquarium parts, cooking tools, and air filters. Aluminum expanded metal sheets are a top choice for projects that require a balance of strength and weight reduction, such as aerospace, marine, and transportation equipment.

Stainless steel, an alloy containing a minimum of 10% chromium, boasts a thin layer of chromium oxide on its surface. This unique feature grants expanded stainless steel products self-repairing capabilities when scratched, along with exceptional resistance to corrosion and rust. Compared to other steel alloys like mild steel, stainless steel is stronger, more durable, and highly resistant to bacteria. These attributes make expanded stainless steel invaluable in diverse environments, from kitchens, clinics, hospitals, and laboratories to outdoor applications, vehicles, buildings, water treatment plants, marine settings, and airplanes. Stainless steel expanded metal mesh is frequently specified for food processing, chemical handling, clean rooms, and architectural projects demanding high performance and hygiene.

Titanium boasts exceptional strength, lightweight properties, resistance to corrosion and heat, and sterility. It matches steel in strength while being 45% lighter. Its biocompatibility makes it ideal for surgical and orthopedic applications. Expanded titanium is highly sought after in military and defense, aerospace, automotive, electronics, and healthcare industries, where strength-to-weight ratio, reliability, and inertness are critical.

Other materials sometimes used for expanded metal products include carbon steel, galvanized steel, nickel, brass, and specialty alloys. Each material offers specific advantages based on the application, environment, and budget. For example, galvanized expanded metal offers superior corrosion protection in outdoor or wet settings, making it a popular choice for fencing, walkways, and construction reinforcement.

Process Details

In transforming metal sheets into expanded metal products, manufacturers begin with the expansion process. Following this, the sheets are shaped and formed to meet custom specifications. For a deeper understanding or to find suppliers that offer custom expanded metal fabrication, continue reading:

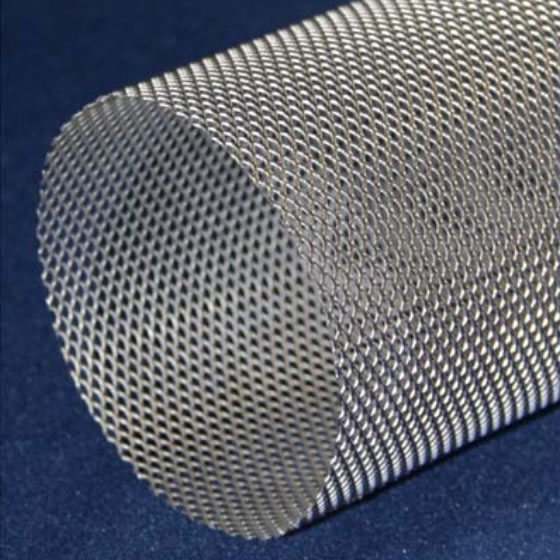

- The manufacturing process for regular and flattened metals begins in the same way. Initially, metal sheets are fed into a machine that presses and expands them. Nowadays, this procedure is typically managed by an automated system, ensuring greater efficiency, repeatability, and precision for high-volume production.

- After expansion, the die repeatedly pierces the sheet in a consistent pattern, typically creating a diamond shape. However, manufacturers also have the flexibility to cut and form custom shapes and patterns to meet specific requirements, including hexagonal, round, square, or even designer mesh patterns for architectural use.

- Next, manufacturers pass the sheet through a hot rolling press, causing the metal to expand, thin out, and flatten. If the original sheet is particularly thick, additional heat and pressure are applied to ensure proper expansion and cutting. This step produces flattened expanded metal, which is smoother and flatter for applications where surface uniformity is critical.

- After this stage, manufacturers can enhance the expanded metal product through various finishing processes, such as annealing to boost corrosion resistance, applying veneers like paint or PVC, galvanization to create galvanized steel, or anodization. Protective coatings, applied either by spraying or dipping, are commonly used after the metal is formed. These coatings not only improve the metal’s properties but also allow manufacturers to alter the surface colors to match design specifications or environmental requirements.

- After this process, manufacturers regard the piece as a completed metal grid or mesh, ready for secondary fabrication, cutting, welding, or forming into finished products like panels, screens, or grating sections.

Are you wondering how to select the best expanded metal for your project? Consider factors such as material, thickness (gauge), pattern (SWD/LWD), open area percentage, and finishing options to ensure optimal performance and appearance. If you need help with custom fabrication, be sure to request a quote or consult with an experienced expanded metal manufacturer for expert guidance.

Design

When manufacturers engage in the expanding metal process, they must carefully consider several factors. Primarily, they need to determine the shape and size of the hole patterns in the expanded metal products according to the specific application requirements. They also need to take into account standard specifications, choose the most suitable metal based on its properties, select the appropriate metal gauge (thickness), and decide on the overall dimensions (length, width, etc.) and texture.

To determine the size of the open areas they plan to create during metal expansion, manufacturers use two measurement methods: SWD and LWD. SWD, or “short way of the diamond,” refers to the width of the openings. LWD, or “long way of the diamond,” indicates the length of the openings. These measurements are calculated based on the required density of air, water, or other substances that must pass through the metal pattern. Properly specifying SWD and LWD ensures that the expanded metal mesh meets the necessary performance for filtration, screening, or structural support.

To tailor an expanded metal product, manufacturers can shape the metal to any specification and apply a variety of paints or coatings. They also have the flexibility to design custom hole patterns. For buyers, understanding these design options is vital—whether you are seeking decorative expanded metal panels for architectural facades or heavy-duty security mesh for fencing applications.

Looking for help specifying expanded metal mesh for a unique application? Contact an expanded metal supplier with your requirements for expert design assistance and material selection recommendations.

Machinery Used

Manufacturers utilize a variety of machines and tools to execute the metal expansion process and the subsequent parts forming procedure. This includes expansion presses, flattening presses, dies, and hot rolling presses. The choice of machinery impacts the quality, speed, and customization capabilities of the finished expanded metal products.

Expansion presses work by pushing metal outward with a stretcher bar while cutting slits into the metal with mechanical knives. Manufacturers typically prefer automated CNC expansion presses over manual ones for their efficiency and precision. CNC-controlled expansion presses can produce intricate, repeatable patterns, enabling rapid production of high-quality expanded metal sheets, mesh, and panels.

Flattening presses live up to their name by flattening and smoothing metal sheets. They are used after perforation and expansion, working through cold rolling. In this process, parallel cylinders apply pressure to the metal as it moves between them, squeezing it into a smooth, even surface. Flattened expanded metal is often specified for architectural, industrial, and safety applications where surface flatness and smoothness matter.

Dies are specialized manufacturing tools that work with presses and forming machines. Crafted primarily from metal, these tools are engineered to match the shape of the intended product. When material is fed through or pressed into the die, it is cut and shaped according to the die’s design. Custom dies allow for the production of unique mesh patterns, custom openings, and specialty products tailored to customer needs.

Hot rolling presses are designed with rollers to flatten metal by working it at temperatures above its recrystallization point. This distinguishes them from cold rolling presses, which operate at lower temperatures. The combination of hot and cold rolling processes gives manufacturers flexibility in achieving the desired material properties and surface finishes.

Interested in learning more about the equipment used in expanded metal manufacturing? Explore our resources on expanded metal machinery or request a facility tour from a local supplier to see the process in action.

Advantages over Similar Processes

Perforated metals and wire mesh are closely related to expanded metals. Perforated metals feature sheets with evenly spaced holes punched into them, while wire mesh is created from interwoven wires forming a grid pattern. Both materials, much like expanded metals, find application across diverse industries for tasks such as filtration, screening, fencing, and architectural design.

While each of the three processes has its own benefits, expanded metals stand out in particular scenarios. They are notably lighter than perforated metals, which simplifies handling and installation. The manufacturing process for expanded metals involves slitting and stretching a single sheet of metal to create a pattern of interlocked strands. This unique structure gives expanded metals added strength and rigidity, often making them more durable than perforated metals, especially in high-stress situations. Expanded metal’s one-piece construction eliminates weak points, making it ideal for safety barriers, machine guards, and impact-prone areas.

Expanded metals offer greater versatility and customization compared to wire mesh. Their openings and patterns can be adjusted to meet specific needs, allowing for a wide range of designs and functions. In contrast, wire mesh is constrained by the thickness and arrangement of its wires, limiting its customization options. Additionally, expanded metals provide improved visibility with more pronounced openings, making them ideal for applications requiring transparency, such as architectural facades and safety barriers. The ability to specify mesh opening size and pattern gives expanded metal an edge in light diffusion, privacy screening, and airflow management.

They also offer the advantage of efficient material use. The manufacturing process involves stretching the metal rather than removing it, resulting in minimal waste. This approach not only leads to cost savings but also makes the production process more environmentally friendly compared to techniques that produce more scrap material. For companies seeking sustainable building materials or aiming to comply with green construction standards, expanded metal is a compelling choice.

In summary, although perforated metals and wire mesh excel in their respective applications, expanded metals provide distinct advantages that often make them the preferred choice. Their lightweight nature, inherent strength, and versatility offer exceptional durability and cost-effectiveness. Moreover, their efficient material usage and enhanced visibility make expanded metals superior to other products in specific contexts, from industrial platforms to modern architectural masterpieces.

Still deciding between expanded metal, perforated metal, and wire mesh for your project? Compare product specifications or consult with an expanded metal specialist to identify the best solution for your application.

Benefits

Expanded metals offer numerous advantages, making them a popular choice in various industries. Their open design enhances ventilation and drainage, providing significant benefits. Whether used as grating in industrial environments, walkways, platforms, or as screens for air or liquid filtration, the interconnected pattern ensures efficient airflow and fluid passage. This feature is particularly valuable in applications where proper ventilation or drainage is crucial for optimal performance and safety, such as chemical processing, water treatment, and building construction.

They offer remarkable versatility, allowing for customization of opening sizes and shapes to suit diverse applications. Their adaptability makes them ideal for a range of uses, from architectural facades to automotive parts and concrete reinforcement. This flexibility ensures that expanded metals can meet a variety of design and functional requirements. For example, custom expanded metal panels can be engineered for acoustic control, sun shading, or aesthetic enhancement in commercial buildings.

Additionally, expanded metals are low-maintenance due to their robust construction, which endures harsh environmental conditions. This makes them ideal for outdoor use where exposure to weather, moisture, or chemicals is common. Their minimal upkeep leads to lower costs and a longer product lifespan. For facility managers and property owners, this translates to reduced total cost of ownership and fewer replacement cycles.

Moreover, expanded metals are environmentally friendly because their production process optimizes material use. The stretching technique generates minimal waste, leading to a reduced environmental impact compared to other manufacturing methods. Many manufacturers also offer recycled-content expanded metal products, supporting LEED certification and sustainable building practices.

Expanded metal products are also easy to install and modify. They can be cut, shaped, welded, or bolted into place, making them suitable for both new construction and retrofit projects. Their anti-slip surfaces, resistance to tampering, and high load capacity make them a trusted choice for public infrastructure, safety walkways, and security fencing.

In summary, expanded metals offer significant advantages across various applications. Their superior ventilation and drainage properties, combined with their versatility and low maintenance needs, make them a practical and reliable choice. Additionally, their eco-friendly production process further enhances their appeal. These benefits position expanded metals as an excellent solution for diverse industries, including construction, architecture, filtration, automotive, aerospace, marine, security, and more.

Ready to discover how expanded metal can improve your project? Contact a leading expanded metal manufacturer for application guidance, samples, and pricing information.

Finding the Right Service Provider

Metal expansion isn’t overly complex, but the difference between an experienced service provider and a novice can be significant. For the best results, partnering with someone who has both extensive experience and a solid reputation is crucial. To assist you, we’ve compiled a list of our most trusted expanded metal suppliers. You can find their company information and profiles interspersed between the paragraphs above. These expanded metal manufacturers offer a wide range of products and custom fabrication services to suit any requirement, from small-scale architectural mesh to large-scale industrial grating.

Before diving into your search, we recommend taking some time to compile a list of your own. Include all your specifications, questions, and concerns. Once your list is ready, use it as a guide during your search. Eliminate any company that doesn’t meet your requirements. Select three or four expanded metal manufacturers that catch your interest and reach out to them. Be sure to discuss your budget, timeline, and delivery preferences. After speaking with each, compare the responses to determine which manufacturer best suits your needs and move forward from there.

Key questions to ask when choosing an expanded metal supplier include:

- What materials and gauges are available for expanded metal sheets, mesh, and panels?

- Can you provide custom fabrication, finishing, or cutting services?

- What are your lead times and minimum order quantities?

- Do you offer product samples or technical support for design and engineering?

- Are your products compliant with relevant industry standards and certifications?

Taking the time to research and vet suppliers will ensure you receive high-quality expanded metal products that are tailored to your application, delivered on time, and priced competitively. For additional resources, view our expanded metal manufacturer listings or >explore our expanded metal FAQs to answer common buyer questions.

Whether you are a contractor, architect, engineer, or purchasing manager, selecting the right expanded metal manufacturer is a key step toward project success. Begin your search now and leverage the benefits of expanded metal for your next construction, industrial, or design project.

What are the main applications of expanded metal?

Expanded metal is widely used for grating, walkways, fencing, architectural facades, filtration screens, automotive parts, concrete reinforcement, and decorative panels. Its versatility makes it suitable for industrial, commercial, and architectural purposes.

Which metals are commonly used to make expanded metal products?

Manufacturers typically use copper, aluminum, stainless steel, titanium, carbon steel, galvanized steel, nickel, and brass to produce expanded metal products. The choice of metal depends on requirements such as strength, corrosion resistance, conductivity, and weight.

How is expanded metal manufactured?

Expanded metal is manufactured by feeding metal sheets into a machine that slits and stretches them into a mesh pattern. The sheets may then be flattened, finished with coatings or treatments, and formed to meet custom specifications for use as grating, mesh, or panels.

What are the benefits of using expanded metal compared to perforated metal or wire mesh?

Expanded metal is lighter, stronger, and more rigid than perforated metal, thanks to its one-piece construction. It offers greater customization of openings compared to wire mesh, better material efficiency, and minimal waste during manufacturing, making it durable and eco-friendly.

How do SWD and LWD measurements affect expanded metal design?

SWD (short way of the diamond) refers to the width, and LWD (long way of the diamond) refers to the length of the mesh openings in expanded metal. These measurements determine airflow, visibility, and filtration capabilities, helping tailor the mesh for specific applications.

What types of finishing options are available for expanded metal?

Expanded metal can be finished with processes like galvanizing, anodizing, painting, or coating with PVC to enhance corrosion resistance, change color, or meet specific application needs. Finishing options improve durability and offer aesthetic customization.

What should I consider when selecting an expanded metal manufacturer?

When selecting an expanded metal manufacturer, ask about available materials and gauges, custom fabrication services, lead times, order quantities, industry certifications, and technical support. Comparing responses ensures you choose a supplier that fits your project requirements.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services