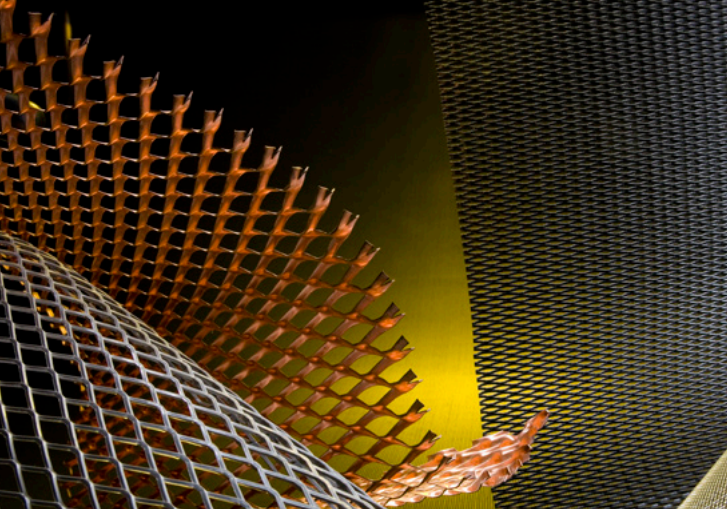

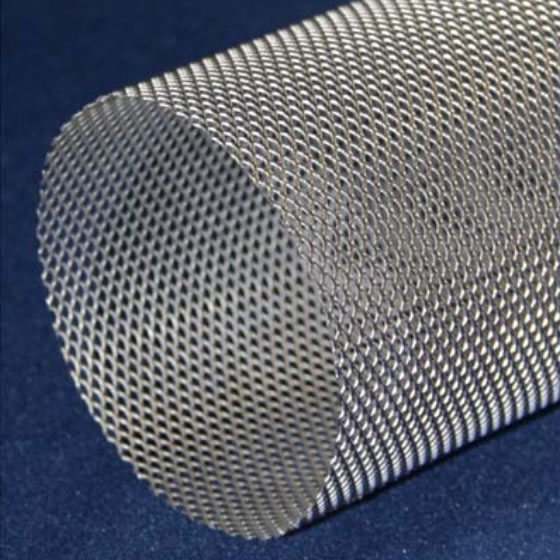

Stainless steel expanded metal is a metal sheet product that has been cut and stretched to create a variety of openings, typically in the shape of diamonds. While creating a beautiful or aesthetic aspect, stainless steel expanded metal offers weight and price savings compared to solid sheets of similar material and a free passage of light, sound, and air. Read More…

At Zauderer Associates, Inc., we specialize in providing high-quality expanded metals tailored to meet diverse industrial needs. Our extensive range of expanded metal products offers versatile solutions known for their strength, durability, and reliability. Leveraging advanced manufacturing techniques, we supply precision-engineered materials ideal for applications such as filtration, security...

Our expanded metal is ideal for a wide range of applications and our teams will work with you every step of the way to guarantee your satisfaction. Our goal is to exceed your expectations and we take pride in providing our customers with outstanding services.

At Expanded Solutions L.L.C., we take pride in producing high-quality expanded metals that serve as durable, versatile solutions for a wide range of applications. We engineer our products to meet demanding performance requirements in industries such as construction, filtration, security, and manufacturing. By expanding metal sheets through precision cutting and stretching processes, we create...

More Stainless Steel Expanded Metal Manufacturers

Stainless steel expanded metal is a highly versatile and durable material designed for strength and longevity in demanding industrial and architectural applications. Thanks to its unique single-piece construction, expanded sheet metal will not unravel and, under normal conditions, retains its shape for many years. The diamond-shaped trusses formed by the interconnected strands and bonds significantly enhance the rigidity and load-bearing capacity of the material. Stainless steel expanded metal is available in a wide range of gauges, opening widths (LWD and SWD), and standard or custom sheet sizes, making it suitable for a multitude of projects across industries.

Stainless Steel Expanded Metal Manufacturing Process

Stainless steel expanded metal is produced by transforming solid stainless steel sheets or coils into an expanded metal mesh with precise, uniform openings. The manufacturing process involves specialized machines and tooling that slit and stretch the metal in a single operation, creating a mesh pattern while maintaining the integrity of the original sheet. This efficient process results in no material waste and produces a lightweight yet robust mesh structure.

During manufacturing, stainless steel sheets or coils are fed into an expanding machine. The metal is then slit and stretched by a precision die consisting of upper and lower blades. The mesh is formed as the die makes alternating cuts and pulls, resulting in consistent diamond-shaped (or sometimes hexagonal) openings. This mechanical process ensures the mesh remains a continuous, single-piece product, maximizing both strength and material efficiency.

The open areas created by the expansion provide an effective barrier against large objects or unauthorized access, while still allowing for optimal passage of air, light, sound, and fluids—qualities essential for many industrial and architectural uses. The entire production process can be customized to achieve specific mesh sizes, strand widths, and thicknesses to meet unique project requirements.

After the initial expansion, stainless steel expanded metal can undergo additional processing such as flattening. In this secondary stage, a rolling mill compresses the raised mesh, producing what is known as flattened expanded metal. Flattened expanded metal offers a smoother surface and a lower profile, making it ideal for applications where uniformity and aesthetics are prioritized, such as architectural cladding, interior design, or safety barriers.

The unique manufacturing process ensures that the stainless steel mesh is stronger per pound than many other metal products and can be expanded up to ten times its original width without loss of structural integrity. The absence of welds or joints means the mesh will not unravel, even if cut at multiple points, and the interconnected strands distribute loads efficiently. This results in a cost-effective, long-lasting solution for demanding applications where both strength and open area are required.

Applications of Stainless Steel Expanded Metal

Are you exploring how stainless steel expanded metal can enhance your project or operation? Expanded stainless steel mesh and sheet products are trusted by manufacturers, architects, and engineers for their reliability, versatility, and visual appeal. The diamond-shaped cutouts and robust design provide a flexible solution for numerous use cases, including both functional and decorative applications. Below, discover the most common and high-value uses for stainless steel expanded metal across key industries:

Industrial and Manufacturing Applications

- Heavy Metal Parts Storage: Automotive manufacturers and industrial facilities depend on stainless steel expanded metal baskets and containers to store and transport heavy components securely. The high load-bearing capacity and resistance to deformation make it ideal for demanding environments.

- Machinery and Equipment Enclosures: Expanded metal mesh is widely used for protective guards, screens, and covers on industrial machines, offering both safety and ventilation.

- Factory & Elevator Flooring: The excellent slip resistance and strength-to-weight ratio make expanded metal a top choice for walkways, catwalks, stair treads, and platforms in factories and warehouses.

- Shot Peening Enclosures: Stainless steel expanded metal is used to contain abrasive materials during surface finishing processes, ensuring operator safety while allowing visibility.

Cleaning and Material Handling

- Washing Enclosed Material: Industries such as aerospace and electronics require components to be cleaned or degreased while kept secure. Stainless steel expanded metal baskets allow for thorough washing and drainage without compromising containment.

- Caging and Sorting: The open mesh structure enables visibility and airflow, making it ideal for caging, sorting bins, and industrial racks.

Architectural and Decorative Applications

- Building Facades & Cladding: Architects use stainless steel expanded metal for modern, visually striking facades, sunscreens, and shading devices that combine aesthetics with functional benefits like light diffusion and airflow.

- Interior Design: Expanded metal panels are popular for decorative ceilings, room dividers, and staircase railings, adding an industrial yet refined look to commercial and residential spaces.

- Art Installations: The formability and strength of expanded metal make it a preferred material for 3D sculptures and public art projects.

Security and Safety Applications

- Perimeter Fencing & Security Partitions: The robust, tamper-resistant mesh is widely implemented in fencing for commercial, industrial, and public infrastructure to prevent unauthorized access while maintaining visibility.

- Machine Guards & Safety Barriers: Expanded metal mesh protects personnel from moving parts in machinery while allowing monitoring and ventilation.

Specialized & Environmental Uses

- Filtration Systems: The customizable mesh size of expanded stainless steel makes it suitable for filters and screens in water treatment, HVAC, and chemical processing.

- Marine Applications: Due to its superior corrosion resistance and durability, stainless steel expanded metal is frequently used for grating, enclosures, and barriers in marine, coastal, and offshore environments.

- Construction Rigging and Scaffolding: The material’s strength and lightweight nature make it ideal for temporary structures and rigging in construction projects.

- Steps and Walkways: Non-slip properties and resistance to wear ensure safety on stairs, ramps, and elevated pathways.

Looking for project-specific advice? Contact an expanded metal supplier to discuss your unique application and discover tailored solutions for your industry.

Expanded Stainless Steel Features & Benefits

Why choose stainless steel expanded metal over alternative materials? This innovative mesh and sheet product offers a powerful combination of performance advantages that make it the preferred choice for a variety of applications. Below are key benefits and distinctive features that set stainless steel expanded metal apart from other metal mesh options:

- Versatility: Suitable for countless industrial, architectural, and security applications, from heavy-duty flooring to decorative facades and protective screens.

- Durability: Stainless steel’s inherent corrosion resistance and toughness provide exceptional longevity, even in harsh or corrosive environments.

- One-Piece Construction: Manufactured from a single metal sheet, the mesh will not unravel or lose its integrity, ensuring long-term reliability.

- Excellent Strength-to-Weight Ratio: The expansion process produces a lightweight mesh with impressive load-bearing capacity, reducing structural weight without sacrificing performance.

- Easy Cutting and Shearing: Expanded metal sheets can be fabricated, cut, and shaped to fit custom requirements with standard metalworking tools.

- Ventilation & Drainage Properties: The open mesh pattern allows for free flow of air, water, light, and sound, critical for HVAC, filtration, and safety applications.

- Cost-Effective Solution: Compared to solid stainless steel sheets, expanded metal uses less material while delivering comparable strength and rigidity, optimizing project budgets.

- Attractiveness: The distinct pattern and finish of stainless steel expanded metal add a modern, industrial aesthetic to any installation.

- High Melting Point and Temperature Resistance: Stainless steel’s ability to withstand high temperatures opens up use in fire-rated assemblies, heat shields, and process environments.

- Sustainability: Stainless steel is 100% recyclable, contributing to green building practices and LEED certification requirements.

Curious about which grade of stainless steel (304, 316, or specialty alloys) is right for your expanded metal application? Ask our experts for guidance on material selection and performance optimization.

Disadvantages and Limitations of Stainless Steel Expanded Metal

While stainless steel expanded metal offers many benefits, it is important to consider its limitations when evaluating material options for your project. Here are several potential disadvantages to keep in mind:

- Welding Challenges: Although stainless steel’s high melting point is valuable in high-temperature applications, it can complicate welding processes. This may restrict the use of expanded stainless steel in certain structural or load-bearing construction scenarios where welded joints are required.

- Material Cost: Stainless steel expanded metal is generally more expensive than expanded metals made from carbon steel or aluminum. The additional cost is often justified by superior durability and corrosion resistance, but budget considerations may affect material selection in cost-sensitive applications.

- Susceptibility to Surface Marks: Stainless steel surfaces can show smudges, fingerprints, and stains more readily than some other materials. While cleaning is straightforward, maintaining a pristine appearance may require regular maintenance in high-visibility installations.

- Weight: In comparison to aluminum expanded metal, stainless steel can be heavier, which may be a factor in applications where minimizing dead load is critical.

- Limited Color Options: Unless powder-coated or otherwise finished, stainless steel expanded metal is available primarily in its natural metallic finish.

If you’re debating between stainless steel, galvanized steel, aluminum, or other expanded metal options, compare material properties, cost, and performance characteristics to ensure the best fit for your project’s requirements.

How to Select the Right Stainless Steel Expanded Metal

Choosing the ideal stainless steel expanded metal product involves several key decision factors. Consider the following criteria to ensure you select the right mesh for your application:

- Mesh Opening Size and Pattern: Determine the required level of security, airflow, or filtration. Fine meshes are ideal for filtration and shielding, while larger openings facilitate drainage and visibility.

- Sheet Thickness and Gauge: Thicker sheets offer greater strength for load-bearing applications, while thinner gauges are suitable for lightweight or decorative uses.

- Material Grade: Common options include 304 stainless steel for general corrosion resistance and 316 stainless steel for enhanced performance in marine or chemical environments. Specialty alloys are available for unique challenges.

- Surface Finish: Choose between raised (standard) and flattened finishes based on appearance, slip resistance, and installation requirements.

- Panel Size and Custom Fabrication: Expanded metal is available in standard sheet sizes or can be custom fabricated to meet specific dimensions, shapes, and installation needs.

- Compliance and Certifications: Ensure your material meets relevant industry standards for safety, strength, and corrosion resistance (such as ASTM, ISO, or local building codes).

Need help with specification or customization? Connect with a stainless steel expanded metal supplier to get expert advice on selecting the right product for your application.

Choosing the Right Stainless Steel Expanded Metal Supplier

Securing the best value and performance from your stainless steel expanded metal investment starts with selecting a reputable, experienced supplier or manufacturer. Here’s how to evaluate and compare suppliers to ensure a successful outcome:

- Extensive Product Range: Look for suppliers offering a comprehensive selection of expanded metal mesh sizes, patterns, and grades to match your project needs.

- Technical Expertise: Choose a supplier with in-depth knowledge of stainless steel properties, mesh fabrication, and application engineering.

- Customization Services: Assess whether the supplier can provide custom fabrication, cutting, or finishing to meet precise project specifications.

- Quality Assurance: Verify that the supplier adheres to rigorous quality standards and provides certifications for their products.

- Customer Support: Responsive, knowledgeable customer service is vital for a smooth procurement process and ongoing support.

- Competitive Pricing and Lead Times: Compare quotes, availability, and delivery schedules to balance cost savings with timely project execution.

To ensure you have the most beneficial outcome when purchasing stainless steel expanded metal, utilize our directory of stainless steel expanded metal suppliers. Each supplier has a detailed business profile highlighting their expertise, capabilities, and product offering. With our website previewer, you can quickly review each supplier’s specializations and track record. Use our streamlined RFQ (Request For Quote) form to contact multiple companies at once—saving you time and effort in sourcing the perfect expanded metal solution.

Ready to take the next step? Request a quote or contact a stainless steel expanded metal expert today to discuss your project requirements and receive personalized recommendations.

Frequently Asked Questions About Stainless Steel Expanded Metal

What are the main benefits of using stainless steel expanded metal?

Stainless steel expanded metal provides superior strength, corrosion resistance, and versatility. Its open mesh design allows airflow, drainage, and visibility, making it ideal for applications ranging from industrial flooring and safety guards to architectural cladding and filtration systems.

How does stainless steel expanded metal compare to other materials?

Compared to carbon steel or aluminum expanded metal, stainless steel offers greater durability, corrosion resistance, and temperature tolerance. However, it is generally more expensive and heavier than aluminum alternatives.

What grades of stainless steel are commonly used for expanded metal?

The most common grades are 304 and 316 stainless steel. Grade 304 is suitable for most indoor and general-purpose applications, while 316 offers enhanced resistance to saltwater and harsh chemicals, making it ideal for marine or chemical processing environments.

Can stainless steel expanded metal be customized?

Yes, manufacturers can produce custom mesh sizes, patterns, panel shapes, and finishes. Custom fabrication services can include cutting, bending, welding, and surface treatment to meet unique project demands.

How do I clean and maintain stainless steel expanded metal?

Routine cleaning with mild detergent and water is usually sufficient. For tougher stains or marine environments, specialty stainless steel cleaners may be recommended. Regular maintenance preserves appearance and prevents corrosion.

Where can I buy stainless steel expanded metal?

Use our supplier directory to find reputable stainless steel expanded metal manufacturers and distributors. Compare product offerings, technical support, and pricing to find the best partner for your needs.

Conclusion: Unlock the Potential of Stainless Steel Expanded Metal

Stainless steel expanded metal stands out as a high-performance, adaptable solution for industries ranging from construction and manufacturing to architecture and marine engineering. Its unique manufacturing process, unmatched strength-to-weight ratio, and enduring visual appeal make it a smart investment for projects demanding both functionality and style.

Whether you need a durable mesh for security, an elegant facade for architectural design, or a robust solution for industrial flooring, stainless steel expanded metal delivers lasting value. Explore our resources, connect with trusted suppliers, and harness the advantages of expanded metal for your next project.

Ready to begin? Browse stainless steel expanded metal products, request a quote, or consult with an industry expert today!

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services