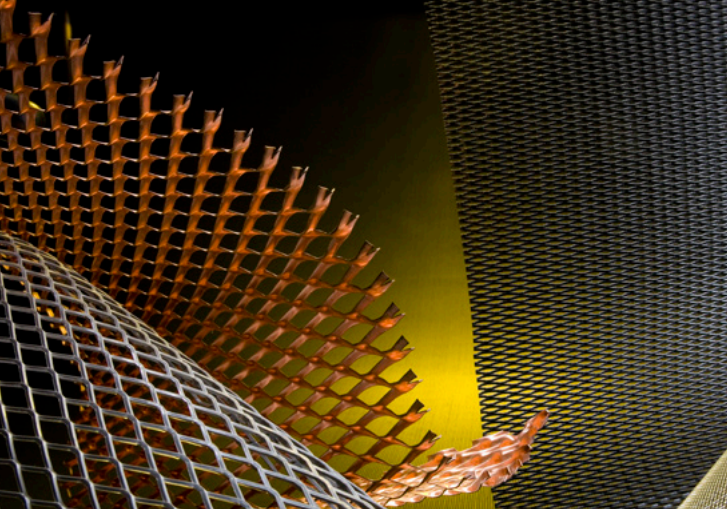

Expanded aluminum, also known as expanded metal, is a unique material renowned for its diverse range of applications. This article aims to shed light on the intriguing world of expanded aluminum, starting with its definition and nomenclature. Essentially, expanded aluminum refers to a metal sheet that has been processed through a specialized expansion technique, resulting in a pattern of interconnected diamond, hexagonal, or circular-shaped openings. This expanded structure grants the material its distinctive name. Read More…

At Zauderer Associates, Inc., we specialize in providing high-quality expanded metals tailored to meet diverse industrial needs. Our extensive range of expanded metal products offers versatile solutions known for their strength, durability, and reliability. Leveraging advanced manufacturing techniques, we supply precision-engineered materials ideal for applications such as filtration, security...

Our expanded metal is ideal for a wide range of applications and our teams will work with you every step of the way to guarantee your satisfaction. Our goal is to exceed your expectations and we take pride in providing our customers with outstanding services.

At Expanded Solutions L.L.C., we take pride in producing high-quality expanded metals that serve as durable, versatile solutions for a wide range of applications. We engineer our products to meet demanding performance requirements in industries such as construction, filtration, security, and manufacturing. By expanding metal sheets through precision cutting and stretching processes, we create...

More Expanded Aluminum Manufacturers

The Creation of Expanded Aluminum

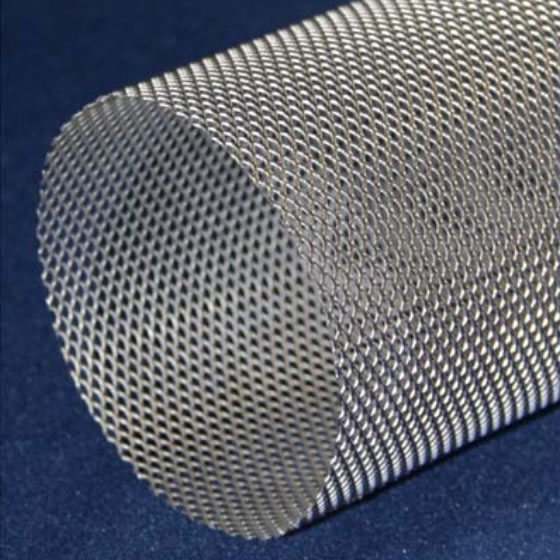

To understand the creation of expanded aluminum, we must first recognize the disparities between it and regular aluminum production. The process begins with a flat sheet of aluminum, which is then subjected to precise cuts and stretches. These actions cause the material to expand, resulting in the characteristic diamond, hexagonal, or circular-shaped openings. Unlike regular aluminum production, the expansion process imparts unique properties to the metal, enhancing its strength, rigidity, and versatility.

Variations in the Creation of Expanded Aluminum

The expansion technique allows for variations in the shape and size of the openings, thus creating different types of expanded aluminum. For instance, some variations feature smaller diamond-shaped openings, ideal for applications that require enhanced structural integrity or resistance to small particles. In contrast, larger diamond-shaped openings offer improved airflow and light transmission, making them suitable for architectural designs or filtration purposes. Hexagonal-shaped openings, meanwhile, provide excellent weight distribution and high strength, making them suitable for industrial and manufacturing applications. Circular-shaped openings, on the other hand, offer a distinctive aesthetic appeal, making them popular in decorative and artistic endeavors.

Considerations Regarding Expanded Aluminum

While expanded aluminum boasts numerous advantages, it is essential to address some potential considerations. To begin with, the production process of expanded aluminum can have an environmental impact, requiring energy and resources. Additionally, the metal's exposed surface may be susceptible to corrosion and rusting over time, necessitating appropriate coatings for protection. Furthermore, recycling and waste management of expanded aluminum can present challenges due to its intricate structure.

Steps to Combat These Considerations

Efforts have been made to mitigate these considerations associated with expanded aluminum. For example, sustainable production practices are being implemented, such as using recycled aluminum and optimizing energy consumption. To combat corrosion, meanwhile, manufacturers have developed specialized coatings that offer enhanced protection and prolong the material's lifespan. Moreover, advancements in recycling and waste management techniques are being explored to address the challenges posed by expanded aluminum's unique structure.

Benefits of Expanded Aluminum

Despite the aforementioned considerations, expanded aluminum boasts a myriad of benefits. Its lightweight nature, coupled with a high strength-to-weight ratio, makes it an ideal choice for applications that require durability without excessive weight. The expanded structure also provides excellent heat and sound insulation properties, making it suitable for use in architectural projects and industrial settings. Furthermore, expanded aluminum offers versatility in design and customization, allowing it to be tailored to specific requirements. Its inherent resistance to weather conditions ensures long-lasting performance, even in challenging environments.

Applications of Expanded Aluminum

The applications of expanded aluminum span various industries. In architecture and building construction, for instance, it finds use in facades, screens, and sunshades, blending functionality with aesthetic appeal. Meanwhile, the automotive industry utilizes expanded aluminum for radiator grilles, air vents, and interior trim, leveraging its lightweight and structural advantages. In the industrial and manufacturing sectors, expanded aluminum serves as walkway gratings, machine guards, and filters, owing to its strength and versatility. Filtration and screening applications also benefit from expanded aluminum's precise aperture sizes and superior airflow characteristics. Finally, expanded aluminum finds its place in decorative and artistic endeavors, where its unique patterns and textures add a touch of elegance and innovation.

The Future and Expanded Aluminum

The future of expanded aluminum holds immense potential for further advancements and applications. As industries continue to seek lightweight and sustainable materials, expanded aluminum stands out as a viable solution. Ongoing research and development efforts aim to refine the production process, reducing energy consumption and environmental impact. Innovations in surface coatings and treatments could further enhance its corrosion resistance and longevity. Additionally, exploring new variations in expanded aluminum, such as incorporating different shapes, sizes, or patterns of openings, could unlock novel applications in areas such as aerospace, renewable energy, and advanced filtration systems. The integration of expanded aluminum with other materials, such as composites or polymers, meanwhile, may result in hybrid structures with enhanced properties. Furthermore, advancements in additive manufacturing techniques, such as 3D printing, may offer exciting possibilities for creating complex and intricate expanded aluminum structures. As technology evolves, expanded aluminum could play a significant role in addressing emerging challenges and driving innovation across a wide range of industries. Its versatility, durability, and unique characteristics position it as a material of choice for the future, paving the way for groundbreaking solutions and designs.

Choosing the Right Expanded Aluminum Manufacturer

To ensure you have the most beneficial outcome when purchasing expanded aluminum from an expanded aluminum manufacturer, it is important to compare several companies using our directory of expanded aluminum manufacturers. Each expanded aluminum manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each expanded aluminum business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple expanded aluminum companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services